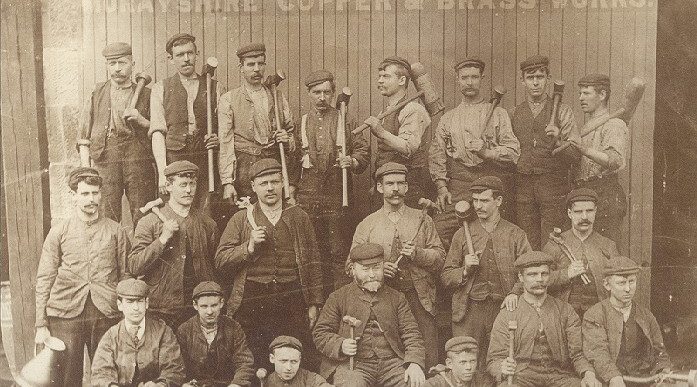

Alexander Forsyth served his time as a coppersmith in Rothes in the 1890’s. The owner of the brass and copperworks at the time was Robert Willison. After finishing his apprenticeship Alexander remained with Willison as a tradesman and then foreman until 1933. It was at this point that he bought the business from the retiring Willison and A. Forsyth and Son was born.

The son was Ernest (better known as “Toot”) and after returning from service in the Second World War he took over the running of the business. Toot quickly introduced new welding techniques to replace the traditional riveting process which helped keep the business moving with times.

In the late 60’s, third generation Richard and William became involved in the business. Richard took over the management of the business in the mid 70’s and oversaw the subsequent diversification and expansion of the company into the group it is today. The company went through rebranding during this time and the company name was reduced to Forsyths.

Today fourth generation Richard Ernest carries on the mantle as Managing Director

Up until the 1980’s the majority of Forsyths revenue was generated from the Scotch Whisky Industry producing copper pot stills and condensers. A slump in whisky production at this time meant that work was scarce and Forsyths had to diversify in order to stay in business.

It was at this point that the company developed its experience in carbon and stainless steels to enter the then busy paper industry. A natural progression from this led us into the oil and gas and pharmaceutical industries. As the company has grown it has broadened its experience into exotic metals like titanium and super duplex whilst maintaining the highest quality of workmanship. It is this constant drive for diversity and reinvestment our people that has underpinned our continued success in this industry. Over the years technology has changed within the industry but grassroots traditions have remained as a base to ensure continuous high standards of quality.